Our softwares scans invoices directly on the warehouse floor. This triggers a database query that returns co-ordinates to our processor, which then picks and confirms orders atutomatically.

1) Doctor prescribe contact lenses

2) Customer get a receipt of the lenses to be picked up

3) Customer comes to shop to pick up lenses

4) Invoices are read by bar code scanners connected to the PLC controls

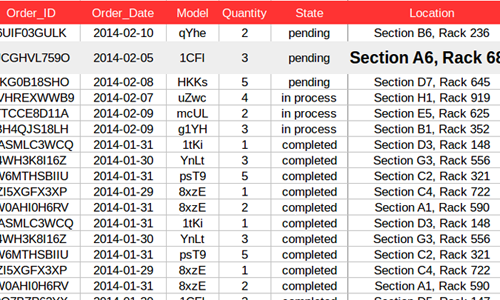

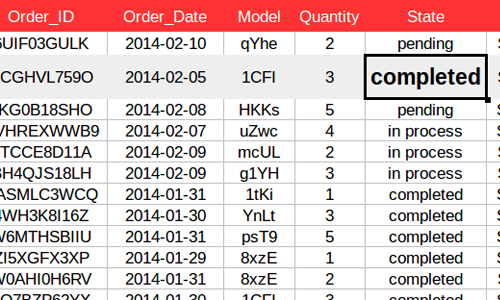

5) System query an SQL dababase in Atlanta, Georgia about the lenses

6) Retrieve lenses’ coordinate and quantity in Mississauga warehouse

7) PLC controlled robotic pick system retrieve lenses and hand to customer

8) Confirmation of the successful pick is then relayed back to the database

We developed all the PLC controls for this project and implemented a DeviceNet network to connect devices (700 solenoid valves) within the pick hardware to the control system.

NRG Innovative Solutions Corp. is one of very few Industrial Automation Integrators with the capability to design devices to solve technological problems of this nature. Conventional integrators would be forced to work with relays and hand-wired interconnects and their customers would be forced to accept increased cost and reduced reliability.

We work hard to offer customers cost effective solutions. We think "out of the box" for our customer's benefit.